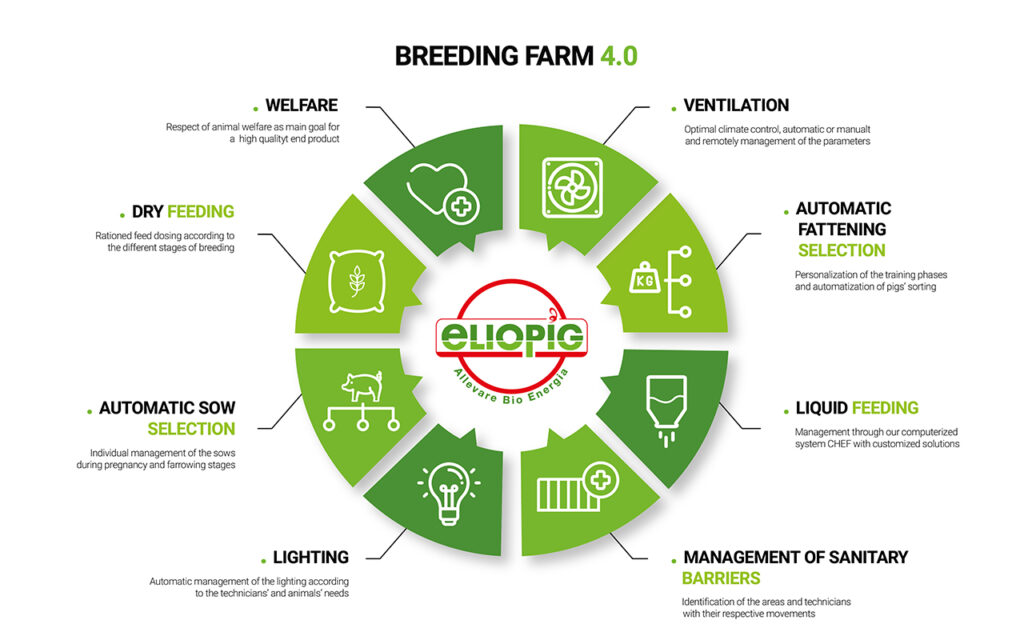

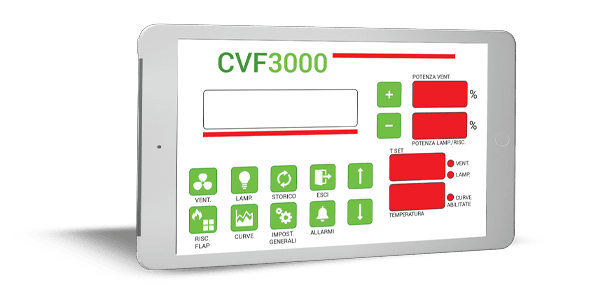

Agriculture 4.0 stands for Artificial Intelligence and robotics to expand, speed up and make more efficient the activities affecting the agricultural supply chain. Electronic and technological management of livestock farming makes it possible to reduce the time spent on repetitive work and to monitor animal health and nutrition. A computerized feeding system allows data and notifications to be generated, controlling and automating processes. This is done through a remote digital interface using instrumentatis such as sensors, wireless collars, automatic scales, feeding robots etc. All these devices are instrumental goods included in the incentives of the “Industry 4.0” model.